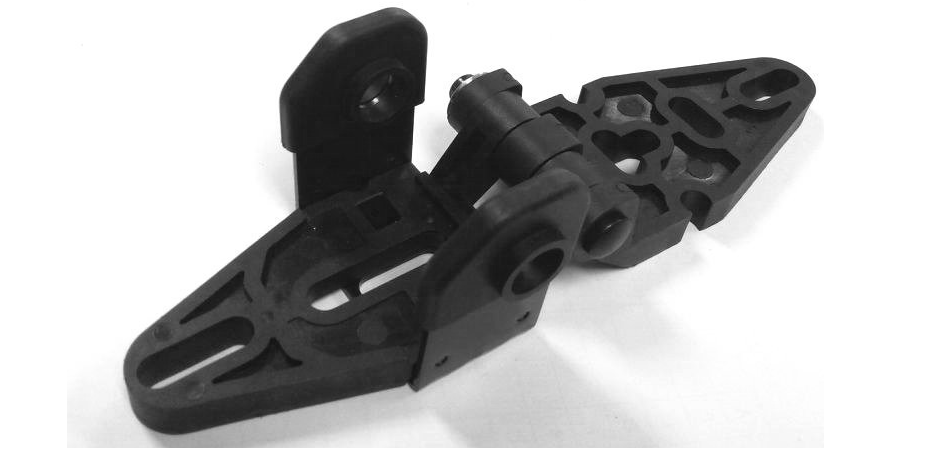

PLASTIC HINGE

Date: 2013

Challenge: Garage door hinges require regular lubricant to prevent issues such as squeaks, noise, and corrosion. This problem is especially critical in coastal areas where salt air accelerates corrosion, despite the use of zinc-coated and galvanized steel hinges. Garage door OEMs, responding to complaints from homeowners and dealers, have been actively seeking cost-effective solutions to address these challenges for their customers.

Solution: Steel and the stamping process will produce the least expensive garage door hinge and is the preferred manufacturing process for many obvious reasons. Though not a preferred method of manufacturing due to the cost of material, tooling, operation, and long development time; Guardian used its knowledge and injection molding capabilities to address their customer's dilemma. Injection molding allows for full process automation, high production output, low waste and minimal post production finishing while holding close tolerances. A glass-filed nylon was chosen for its high impact strength, thermal stability, good sliding friction, and damping properties as well as processing ease for a quiet, corrosion free, reliable product for added value applications.